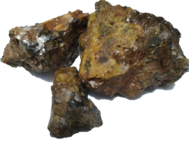

Silica Sand

Silica sand is a general term for quartz sand with high content of silicon dioxide (SiO2), which is distributed in layers or sand dunes on the ground.

In estuaries or coasts, silica sands are deposited with shore sand, collectively referred to as natural silica sands.

The standard for composing silica sand must contain at least 95% silicon dioxide and 0.6% iron oxide.

The difference between the mining and processing methods of silica sand is as follows:

Artificial silica sand, washed sand, scrubbed sand, selected (flotation) sand, etc...

Due to the high melting point and low thermal expansion coefficient of silica sand, it exerts good fire resistance performance under high temperature exposure.

Application

Silica sand is a common industrial raw material, widely used in glass, casting, ceramics and refractory materials, metallurgy, construction, chemicals, plastics, rubber, abrasives, coatings and other industries.