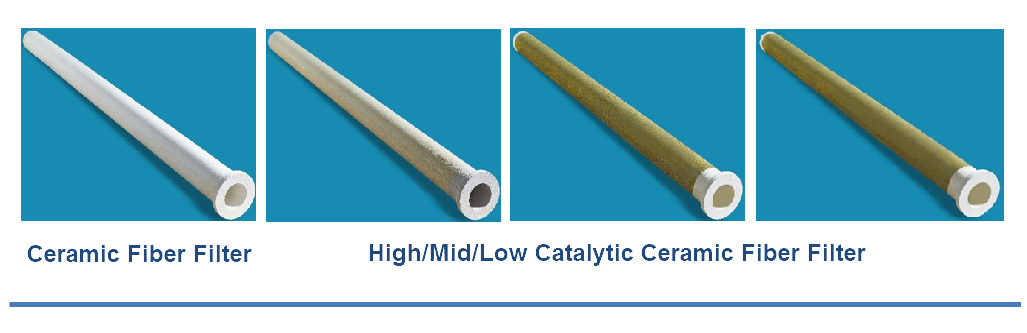

Catalytic Ceramic Filter

t Feature

Ceramic Filter and Catalyst Ceramic Filter are Taiwan made products mainly applied to filter industrial waste gas, remove dangerous pollutants and recycle powder processed at high temperature.

|

|

Replace Traditional Bag Filter: Compatible with standard bag filter design concepts. |

|

|

High-temperature & Corrosion Resistance: Better performance than traditional filter bag. |

|

|

Long Lifetime: Longer lifetime than traditional filter bag. |

|

|

Thermal Recovery: After removal of dust & acid, the clean exhaust can improve the value of thermal recovery. |

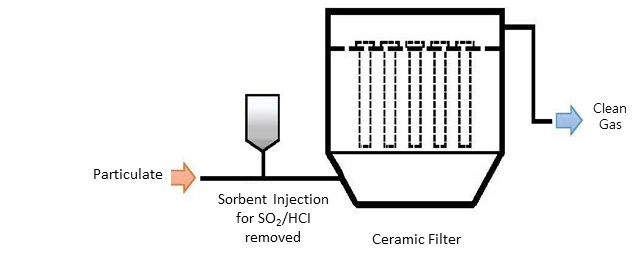

T-01-3000 Ceramic Filter - Target pollutants: Dust on process + Dust from

deSOx process

|

|

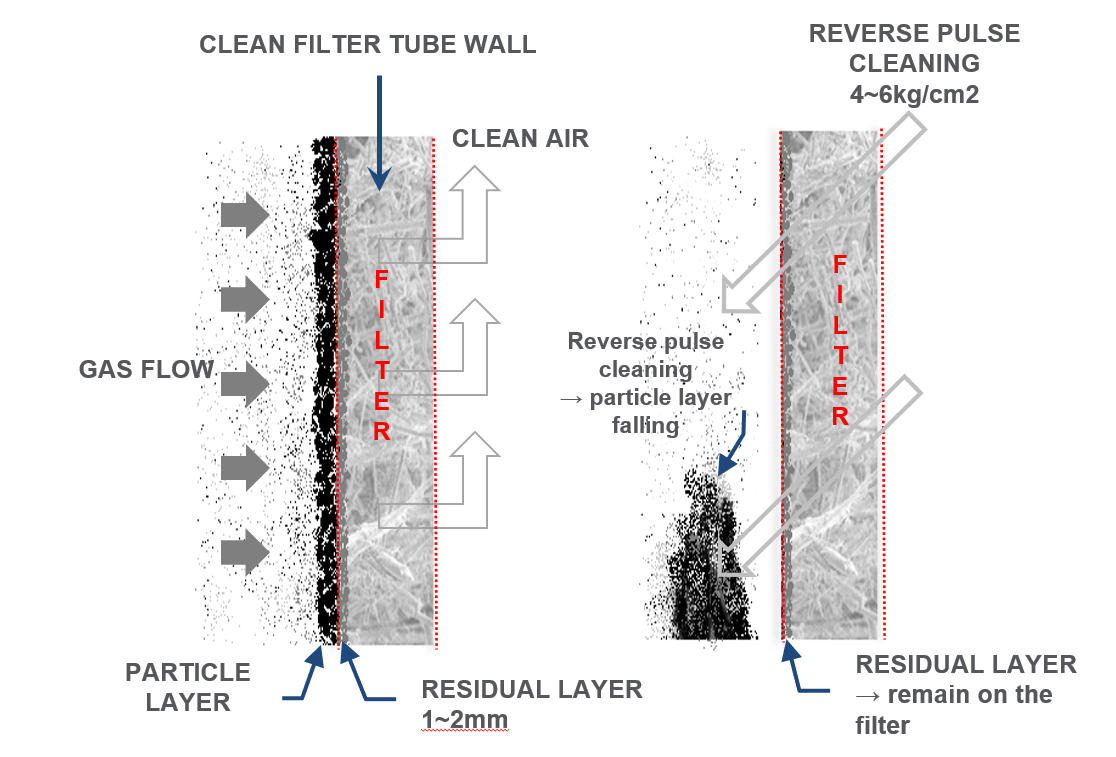

The ceramic fiber filters are installed on the plates of dust collector directly and can be operated under high temperature. The solid structure provides high filtration efficiency and stability under long-run operation.

|

|

|

Assist to DeSOx: Use dry or semi-dry FGD and variety of alkali sorbents such as Sodium Bicarbonate (NaHCO3), Sodium Hydroxide (NaOH) or Hydrated Lime (Ca(OH)2) to remove acid gas (SO2, HCl, HF…) Filter dust collector can be regarded as a DeSOx reactor. The surface of filter is full of lime cake to increase the reaction efficiency. |

|

|

Operating Temperature: 750°C Instant Peak Temperature: 900°C |

|

|

|

|

Ceramic Fiber Filter – Filtration Mechanism

|

|

|

|

|

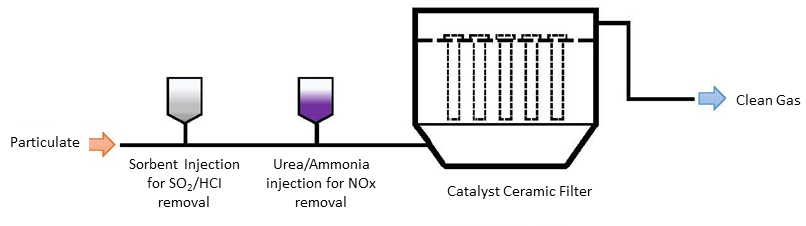

Catalytic Ceramic Filter - Target pollutants: Particulate /

Dust generated from SOx and Acid Gas removal process/ Nitrogen Oxides / Dioxins

|

|

In addition to dust filtration, it can remove acid gas (SO2, HCl, HF…) by injection of alkali reactants and remove NOx by adding ammonia and urea.

|

|

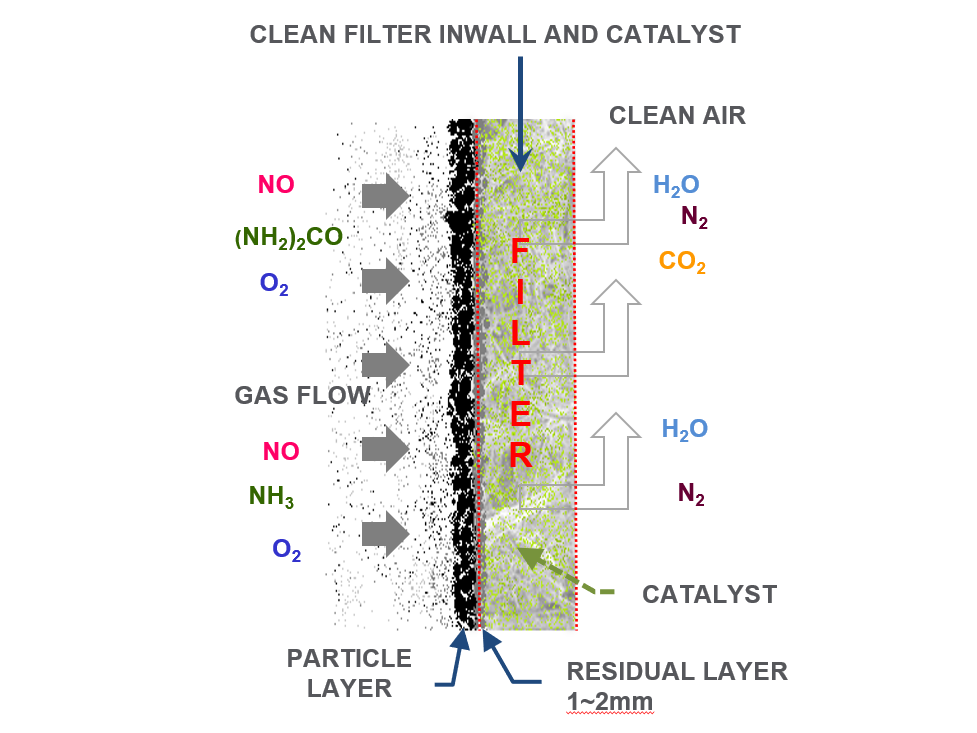

|

Catalyst distributed throughout filter element structure to accelerate the reaction of NOx removal.

|

|

|

High-Temperature Catalyst- The optimal operating temperature: 330-420°C, and max. 420°C. Mid-Temperature Catalyst- The optimal operating temperature: 250-350°C, and max. 350°C. Low-Temperature Catalyst- The optimal operating temperature: 175-250°C, and max. 250°C. 4NO+4NH3 (Ammonia)+O2---4N2+6H2O 4NO+2(NH2)2CO (Urea)+O2---4N2+4H2O+2CO2 |

|

|

|

|

Catalytic Ceramic Filter – Filtration Mechanism |

|

|

|

|

t Application

- Used for industrial pollutants filtration such as particulate, dust, HCl, SO2, and NOx.

- For incinerators, glass furnaces, cement production, boiler, gasification processes, soil remediation, ship/harbor APC, catalyst/heavy metals recovery, mineral processing, metal smelting, power plants, sludge incinerator, lime kiln and so on.

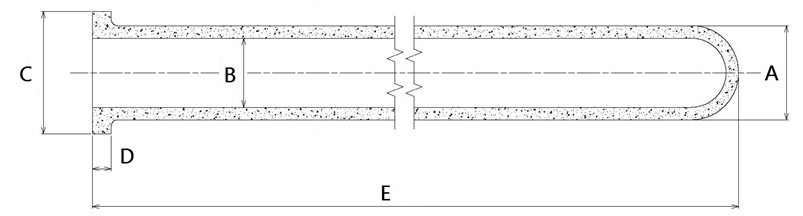

t Specification

- Size Dimension of Ceramic Filter

|

Code |

Item |

Unit |

Size |

|||||

|

A |

O.D. of ceramic filter |

mm |

150 |

60 |

||||

|

B |

I.D of ceramic filter |

mm |

110 |

40 |

||||

|

C |

O.D. of flange |

mm |

195 |

80 |

||||

|

D |

height/thickness of flange |

mm |

30 |

20 |

||||

|

E |

length of ceramic filter |

mm |

3000 |

25001 |

2000 |

15001 |

15001 |

10001 |

|

F |

filtration surface of element |

m2 |

1.3 |

1.07 |

0.83 |

0.6 |

0.24 |

0.145 |

13M & 2M in length (OD150) are standard products and other size can be customized.

t System Operation

|

Product |

Description |

Temperature |

|

T-01 Ceramic fiber filter |

Max. working temp. |

750°C |

|

Min. working temp. |

Acid dew point+20°C |

|

|

H-01 High-temp Catalytic ceramic fiber filter |

DeNOx max. temp. |

420°C |

|

DeNOx working temp. |

330~420°C |

|

|

M-01 Mid-temp Catalytic ceramic fiber filter |

DeNOx max. temp. |

350°C |

|

DeNOx working temp. |

250~350°C |

|

|

DeNOx min. temp. |

ABS dew point (usually at 240~270°C) |

|

|

Dioxins |

180~230°C |

|

|

L-01 Low-temp Catalytic ceramic fiber filter |

DeNOx working temp. |

175~250°C |