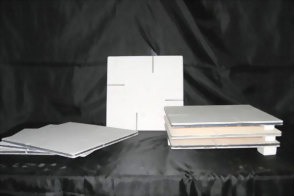

Sandwich Series Products

® Features

The composite sandwich product made of silicon carbide substrate and oxide panel features as high-temperature strength of SiC and low-pollution of oxide. It is applicable to high temperature up to 1450oC or high-load multi-layer and quick-sintering conditions, and can be used effectively to substitute for Mullite to successfully reduce the cost and increase the yield on firing.

® Application

- For electronic and artistic ceramics as manganese, zinc soft magnetic materials.

- For direct or indirect firing of magnetic materials.

- For quick firing or high-density firing under 1450oC.

- For protective gas firing conditions.

® Specification

|

Chemical Composition |

Item |

Unit |

Result |

||

|

SiC |

wt% |

89.5 |

- |

||

|

SiO2 |

wt% |

8.5 |

- |

||

|

Al2O3 |

wt% |

0.7 |

98.5 |

||

|

Fe2O3 |

wt% |

0.6 |

- |

||

|

Physical Properties |

Bulk Density |

g/cm³ |

2.7 |

2.8 |

|

|

Apparent Porosity |

vol% |

11.60 |

22 |

||

|

Flexural Strength |

room temp. |

kg/cm² |

≦400 |

||

|

1200 ℃ |

kg/cm² |

≦500 |

|||

|

Thermal Expansion Coefficient (RT-1000 ℃) |

/℃ |

4.8×10-6 |

|||

|

Heat Transfer Rate (1200 ℃) |

Kcal/(m.h. ℃) |

13.8 |

|||

|

Refractoriness under Load T2 (3kg/cm²) |

℃ |

1750 |

|||