Single-walled Carbon Nanotube (SWCNT) / Carbon Nanotube Dispersion

|

|

||||||||||

|

|

||||||||||

|

Carbon Nanotube |

||||||||||

|

|

||||||||||

|

|

||||||||||

|

Product Category |

||||||||||

|

|

||||||||||

|

Single Walled Carbon Nanotube (SWCNT) |

||||||||||

|

|

||||||||||

|

Carbon Nanotube Dispersion |

||||||||||

|

|

||||||||||

|

Semiconductor Carbon Nanotube |

||||||||||

|

|

||||||||||

|

Carbon Nanotube Yarn |

||||||||||

|

|

||||||||||

|

Carbon Nanotube Tape |

||||||||||

|

|

||||||||||

|

CUSTOMIZED PRODUCTS |

||||||||||

|

We also provide customized product. Depending on your request or usage. Synthesis .Other CNT diameter (for example, 0.9nm, 1.3nm, ... and so on) .More short/long CNT length .Other single/double ratio Dispersion .Other solvent .More short/long dispersion length Separation .Other CNT diameter .Other density Coating .Deposition to Film(using Spray Coater) CONTACT US for customized product.

|

||||||||||

|

|

||||||||||

|

◆About Carbon Nanotube (CNT) |

||||||||||

|

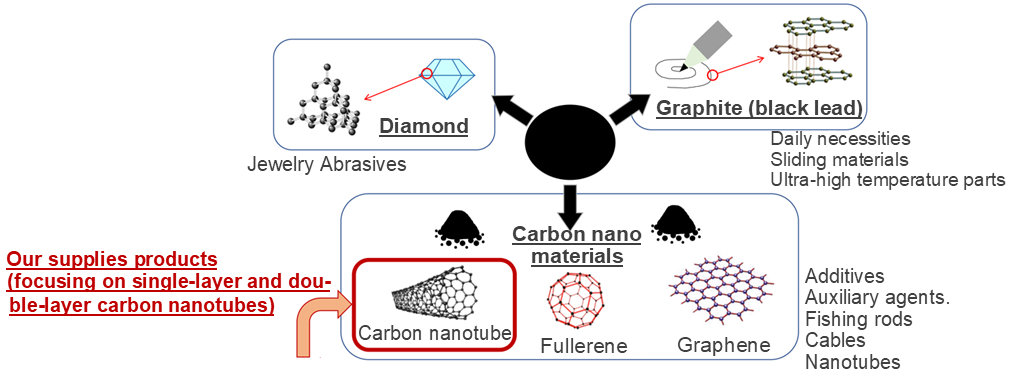

What is nano carbon material? A member of the carbon family composed of carbon atoms. A general term for nanoscale (nm-sized) carbon materials within the carbon family.

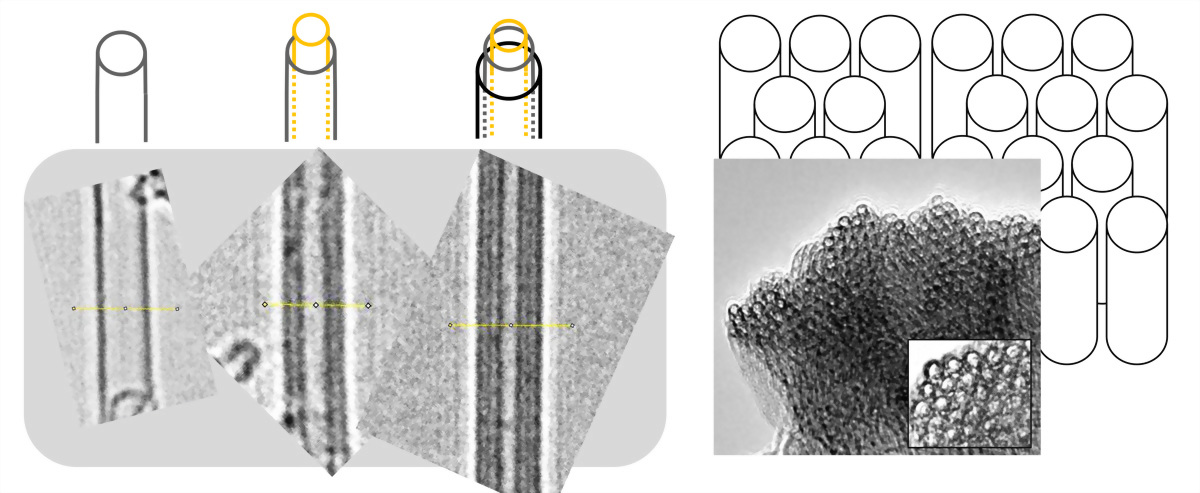

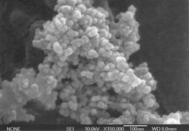

What is carbon nanotube? Cylindrical substances composed of carbon atoms. They have a diameter on the order of nanometers and a length on the order of micrometers, exhibiting flexibility. They also exhibit a nested structure (the number of nests is referred to as the number of layers, such as monolayer (one layer), bilayer (two layers), trilayer (three layers), and so on). Carbon nanotubes have a strong tendency to agglomerate with each other. Two types coexist, behaving either as metallic or semiconducting.

|

||||||||||

|

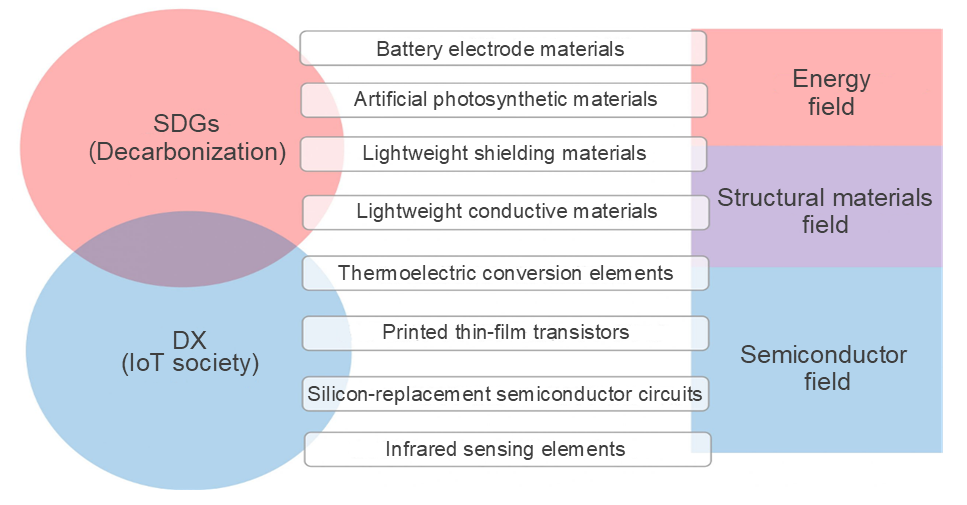

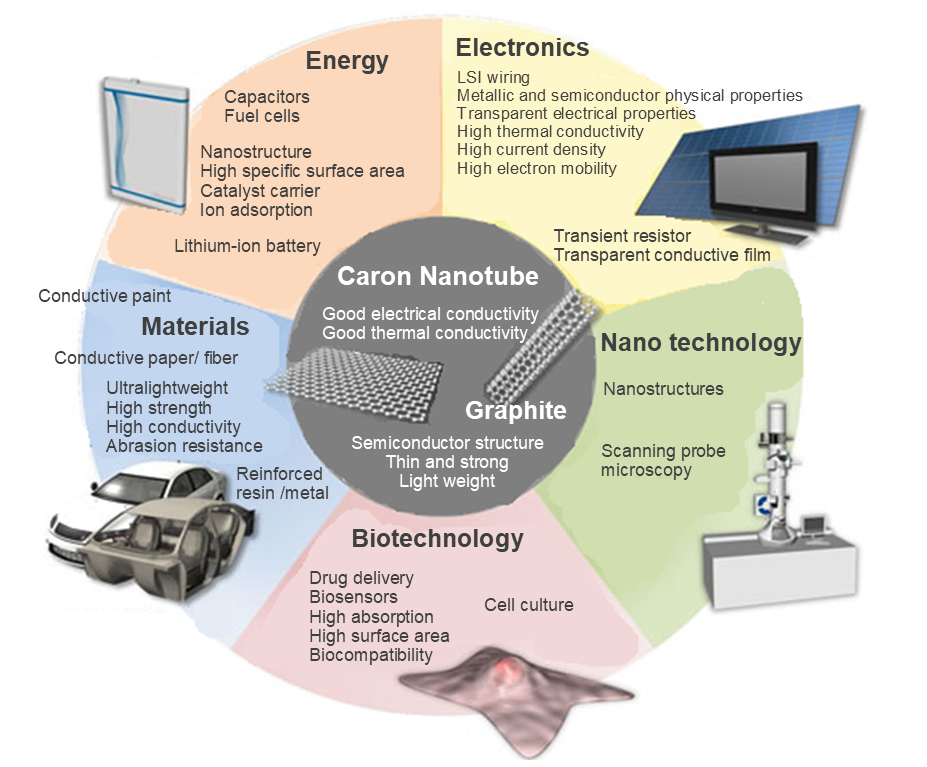

Application of single-walled carbon nanotubes (SWCNT) Single-walled carbon nanotubes play a crucial role as next-generation materials in realizing a society where both people and the planet can thrive and remain healthy.

|

||||||||||

|

Applications Carbon nanotubes are expected to have a wide range of applications in fields such as energy, electronics, nanotechnology, biotechnology, materials, and more. .What can be done with carbon nanotubes

Ø Electornics: Carbon nanotube and graphene can be used to replace a rare metal (indium) which is indispensable for making touch panels, flat-screen TVs, solar batteries and other products.

Ø Energy: Carbon nanotube increases the capacity of lithium-ion rechargeable batteries and supercapacitors (electric double-layer capacitors) to prolong lifespan.

Ø Materials: Adding a small amount of carbon nanotubes to plastic or carbon fiber composite materials creates even lighter, stronger materials.

Ø Biotechnology: Culturing of cells and vaccines can be done efficiently.

|

||||||||||

|

|

||||||||||

|

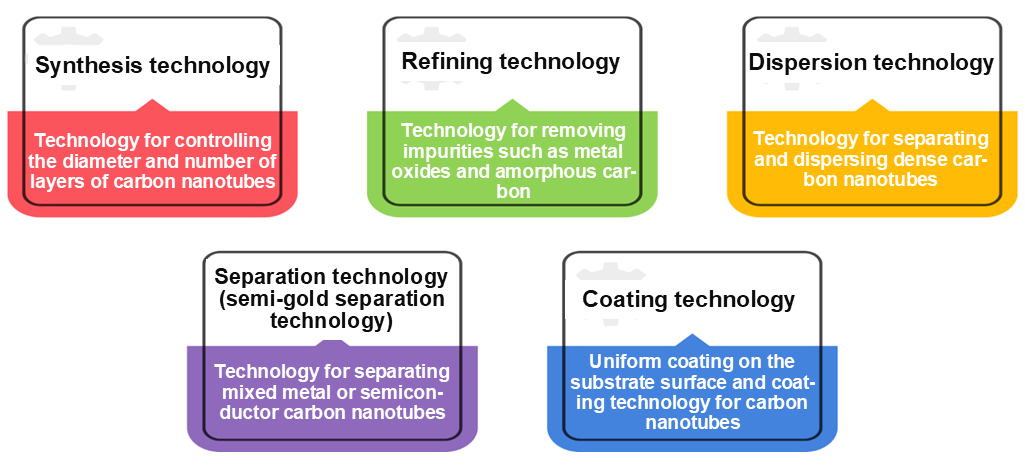

Carbon nanotube (CNT) Technologies |

||||||||||

|

|

||||||||||

|

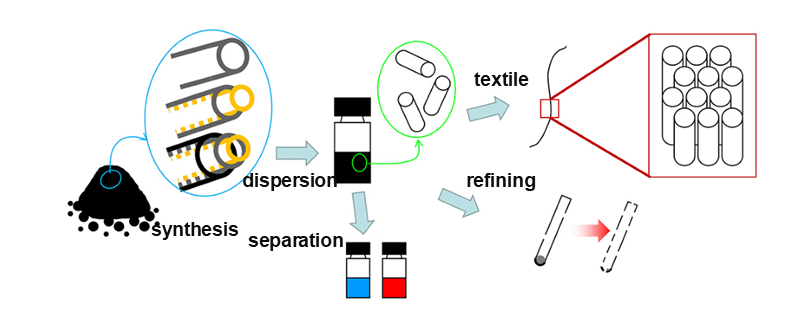

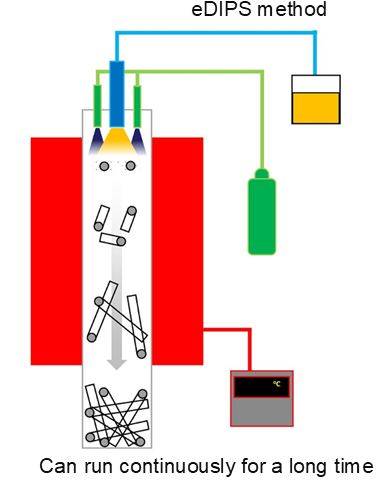

Synthetic technology 1. eDIPS The eDIPS method is a type of vapor-phase flow method based on chemical vapor deposition (CVD). In this method, metal catalyst and carbon source are sprayed in a mist form from a nozzle at the top of the reaction tube, using a carrier gas (H2) for supply. The metal nanoparticles are suspended and during the flow process from the upper to the lower part of the reaction tube, single-walled carbon nanotubes are synthesized in a cotton-like structure and deposited in the collection chamber at the bottom of the reaction tube.

|

||||||||||

|

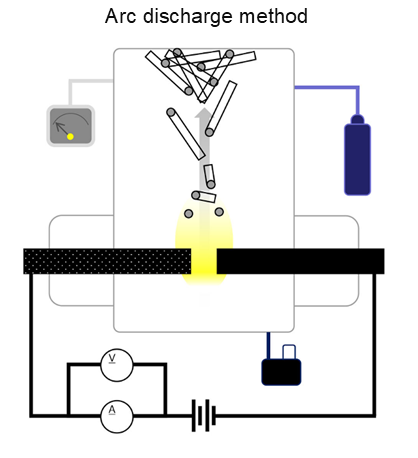

Synthetic technology 2. Arc The arc discharge method is a synthesis technique where an arc discharge is generated between two carbon electrodes, causing the anode electrode to vaporize due to the heat, resulting in the formation of single-walled carbon nanotubes (SWCNTs). The carbon electrode on the anode side is doped with a metal catalyst. When the electrode vaporizes, the metal catalyst also evaporates into a gaseous state, serving as a starting point for the generation of single-walled carbon nanotubes.

|

||||||||||

|

Purification technology During the synthesis of carbon nanotubes, it is common to use a metal catalyst as a starting point for their growth. However, immediately after synthesis, the nanotubes may contain impurities derived from the catalyst, as well as carbon impurities. Therefore, a purification process is necessary to remove these impurities after synthesis. Our company possesses reliable purification techniques to achieve high purity levels in carbon nanotubes.

|

||||||||||

|

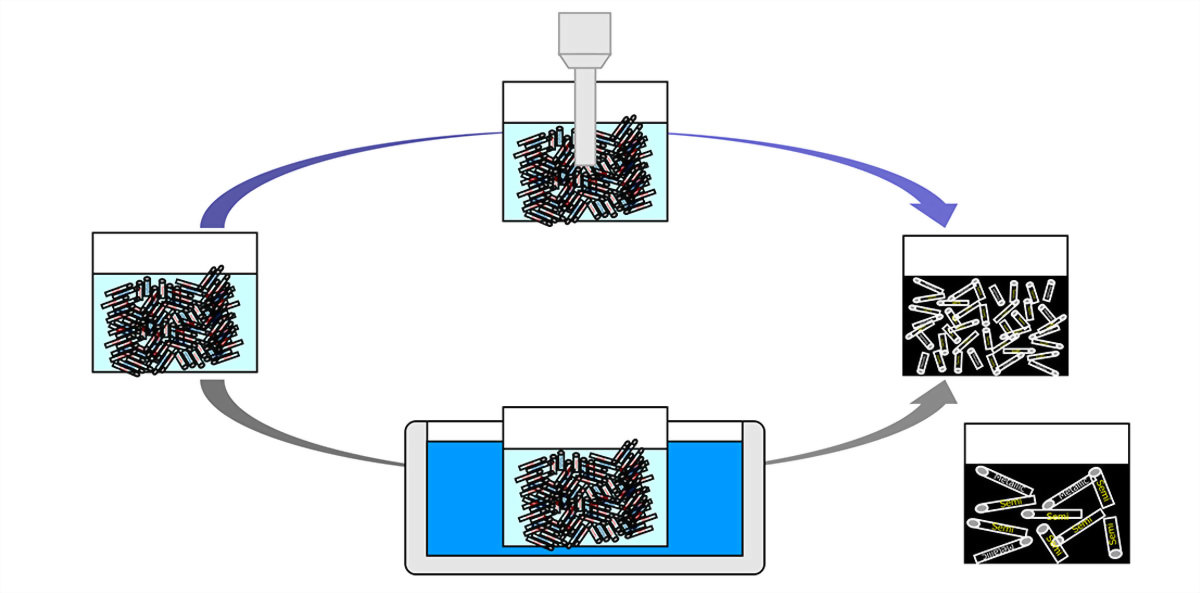

Dispersion technology Carbon nanotubes (CNTs) tend to form bundles or agglomerates due to strong π-π interactions and van der Waals forces, making their dispersion difficult in water and organic solvents. Furthermore, it is crucial to achieve dispersion without compromising the aspect ratio (length) of CNTs in order to exhibit their electrical and thermal conductivity properties. We have developed a proprietary technique called the MN method, which enables high conductivity dispersion while maintaining a high aspect ratio of CNTs. This breakthrough allows for the realization of their desirable electrical and thermal properties.

|

||||||||||

|

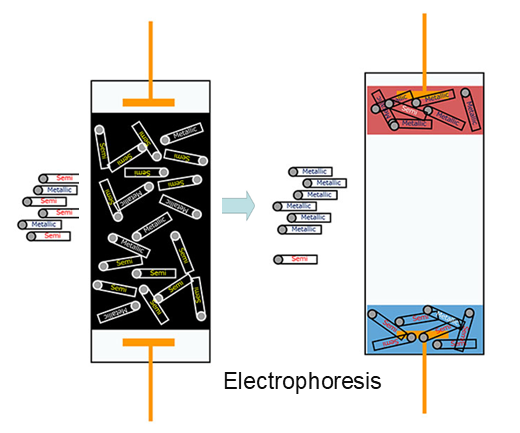

Separation technology NEC and the National Institute of Advanced Industrial Science and Technology (AIST) have successfully developed a technique called the Electric Field-Induced Layer Formation (ELF) method for the separation of high-purity semiconductor-type single-walled carbon nanotubes (SWCNTs) without the use of ionic surfactants. With this method, they achieved a separation purity of over 99%. This breakthrough enables the production of high-performance ink materials without the need for dispersants that can negatively affect device performance.

|

||||||||||

|

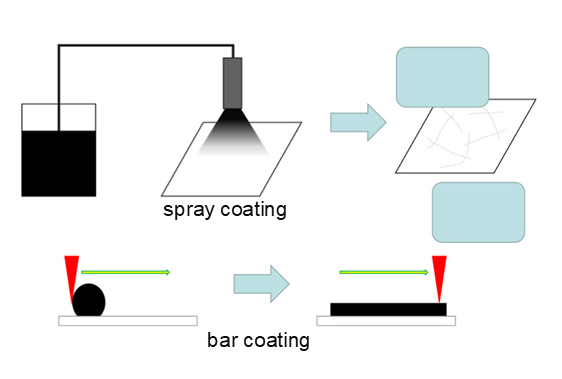

Coating technology We have two types of coating methods, spray coating and bar coating, for the dispersion liquid used in our company. The spray coating is customized for CNT specifications and optimized to instantly dry easily agglomerating CNTs during substrate spraying, ensuring the dispersion state is maintained while effectively depositing CNTs onto the substrate. This allows for the formation of a high-quality coating layer. On the other hand, the bar coating method is used to apply a uniform liquid film onto the substrate and is utilized based on specific applications or substrate requirements.

|

||||||||||

|

|

||||||||||

|

|