Catalytic Filter Bag

|

High Effiency Catalytic Filter Bag |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

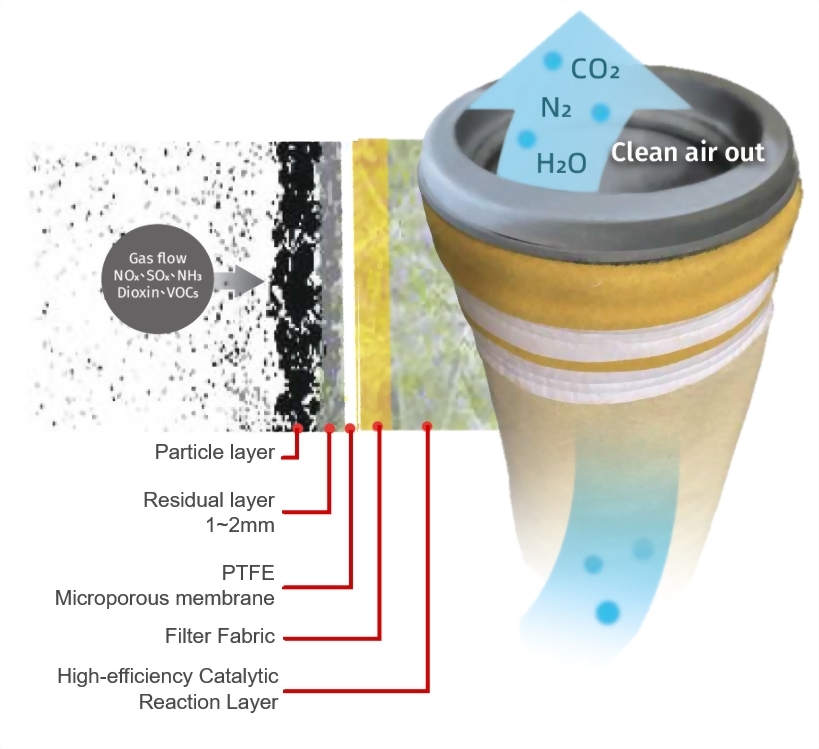

l Multi-layer Structure for Longer Reaction Time and Higher Efficiency The internal layer contains a high catalyst load. Its thicker catalytic layer extends reaction time (0.35–1s), delivering higher conversion and removal efficiency than other brands at the same filtration velocity.

l Multi-functional Catalyst Proprietary formulation enables DeNOx at medium/low temperatures and decomposition of dioxins and VOCs.

l Integrated Treatment With upstream alkaline and reducing agents, the system removes acid gases, dust, SO₂, NOx, and dioxins in one process.

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Structure of High-Efficiency Catalytic Filter Bags |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Membrane structure + dust cake barrier = superior dust collection efficiency |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Catalytic Filter Bag –Application Industries |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

.Waste (liquid) incineration .Biomass power plant .Cement and lime kilns .Iron, Steel sintering/coking .Metal smelting/foundry .Glass kilns .Boiler |

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Catalytic Filter Bag – Advantages & Size Dimension |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

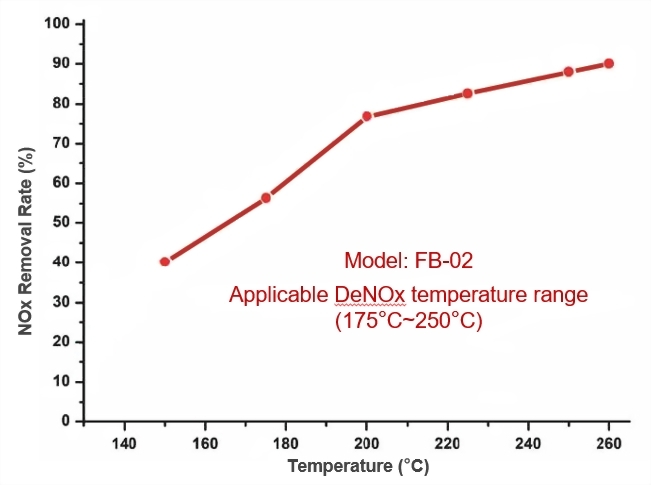

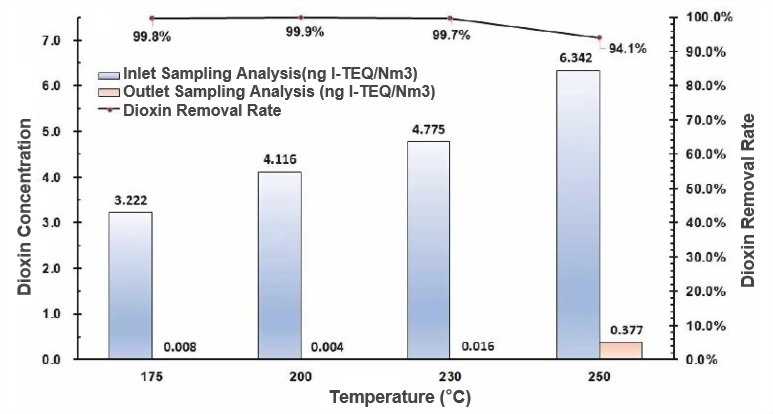

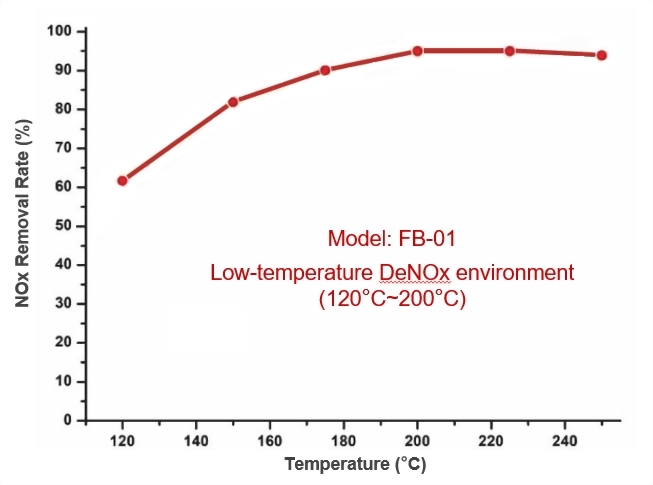

l Selected hydrophobic, hydrolysis-resistant, and breathable customer-specified materials. Resistant to acidic and alkaline gases l High catalyst loading; excellent removal efficiency l Anti-deformation: withstands >200,000 pulse-cleaning cycles l Long abrasion life: filter bags and cages do not suffer multi-point wear damage from continuous friction l ESG-oriented product supporting environmental sustainability l Dimensions vary based on equipment type, gas flow rate, operating temperature, and required filtration efficiency. l Custom diameters and lengths available upon request. l Catalyst type: FB-01 (low-temp catalytic filter bag): for deNOx 120~200°C FB-02 (mid-temp catalytic filter bag): for deNOx 175~250°C, for Dioxin removal 175~230°C |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Dual DeNOx and Dioxin Removal Efficiency |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Dioxin Removal Efficiency |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

With vanadium-based catalysts, dioxins react with oxygen and decompose into non-toxic substances such asCO2, H2O, and HCl. Reaction (oxidation): C12HnCl8-nO2+(9+0.5n)O2=(n-4)H2O+12CO2+(8-n)HCl

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Ultra-Low Temperature Catalyst Product DeNOx Removal Efficiency |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

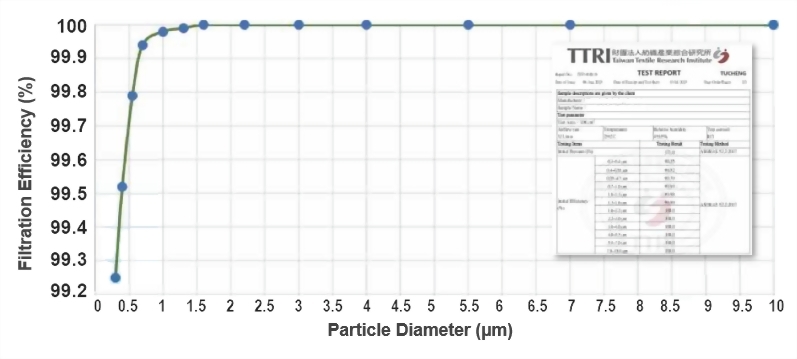

Catalytic Filte Bag - Particle Filtration Efficiency Distribution |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Removal rate for particles ≥ 0.2µm: 99.2~100%

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Catalytic Filter Bag Fabric - Third-Party (TTRI) Test Result |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||