Referthermo

|

Referthermo (Monitor the firing process) |

Firing process is typically controlled by monitoring the thermal profile, but in most cases the actual thermal history of the products in the kiln varies depending on many factors such as the type of kiln and/or the heat capacity.

Referthermo is a standard reference material with highly precise material composition, granularity and compact density, used for controlling the condition of the firing process within the kiln.

The firing conditions can be controlled by firing the referthermo and the ceramic object at the same time, and measuring the size of referthermo after firing.

|

Feature |

l Since firing conditions can be standardized, comprehensive technical data can be shared and comparative evaluations can be made.

l It can be used continuously on a regular basis, and can be applied to abnormal management and statistical quality management of firing kiln.

|

Application |

l Any firing Process where quality control is strictly required such as Fine Ceramics, Sanitary ware, Pottery, Porcelain and so on.

|

Packing |

200pcs/box (50pcs/inner plastic tube x 4 tubes) |

|

Origin |

Japan |

|

Usage |

|

Fire the referthermo at the control place, and measure the size with a micrometer after cooling to room temperature. (Please note that it should be measured after being left at room temperature more than 1 hour.)

|

|

Management Control |

|

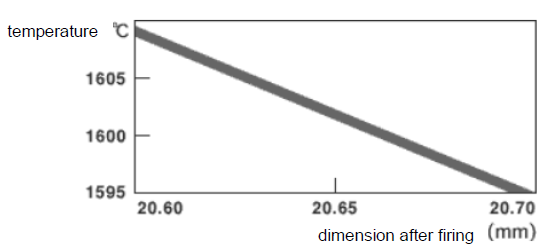

Compare the dimensions measured above to this table and use the indicated temperature as a control. The indicated temperature is not the actual physical temperature, but an indicator applied to the overall thermal history of the fired object. The table sheet is made in use of temperature profile at 200°C/hr rising, 2 hours retention and 300°C/hr falling.

|

|

Dimension (mm) |

Temperature (°C) |

|

20.65 |

1601 |

|

20.66 |

1600 |

|

20.67 |

1599 |

※Note:

If referthermo is used in a vacuum furnace with a low oxygen concentration atmosphere, some components will evaporate. Be aware that the stove may be contaminated.

Operating Temperature Range by Type

|

Referthermo Type |

Operating Temperature Range |

Tolerance |

|

H |

1400~1700°C |

±10°C |

|

M |

1200~1500°C |

±10°C |

|

L |

1050~1300°C |

±10°C |

|

L1 |

800~1150°C |

±15°C |

|

L2 |

600~900°C |

±15°C |